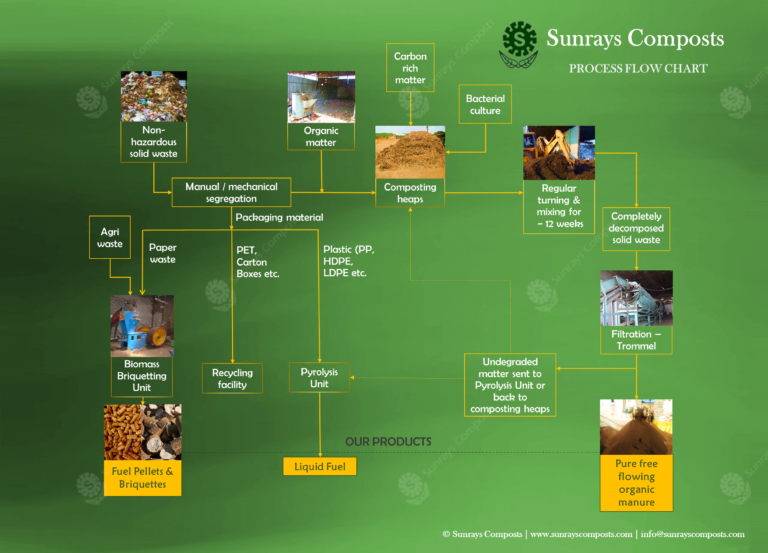

Segregation

The waste that we receive is segregated into bio-degradable organic material and non-biodegradable inorganic materials. Segregation involves both manual and mechanical operations. We systematically remove the packaging from all the goods, separating the plastics from organic materials.

Processing organic matter

High moisture organic material

The remainder of the organic material is sent to composting piles. These are sprayed with bacterial cultures to kickstart the decomposition process. These piles are frequently turned and mixed with JCBs to ensure aeration. In about 90 to 120 days the composting piles are ready for filtration, where the non-biodegradable materials and inert materials such as stones, coconut shells, cloth etc are filtered out and pure, free flowing organic manure is obtained.

The material obtained from this process is completely odour-free. The manure and then tested for its nutrient value, packed and stored.

High calorific value material

Organic material that is of high calorific value/low moisture content is used to manufacture briquettes. In this process, the segregated organic materials are mixed with agricultural rejects such as groundnut husk, coffee husk, saw dust etc. in predetermined proportion. If required the organic material is pulverized to ensure proper mixing. This is fed into the briquetting machine where the die and ram technology are used to compact the organic matter into the required shape. The briquettes are allowed to dry and then packed. Briquettes are an excellent substitute for wood chips and coal in boilers.

We convert the nearly dry organic matter into fuel pellets by extrusion. Pellets thus manufactured by us are even better in calorific value and energy efficiency.

Packaging materials

At Sunrays Composts, the entire industrial waste processing process is streamlined to take care of every kind of packaging that wastes come in with.

The packaging material segregated from the waste are further divided into three different categories.

- The burnable paper waste is powdered and used in the briquetting operation.

- Recyclable materials such as glass and metal are sent to the recycling facilities.

- The plastic packaging materials are segregated either via pyrolysis or co-incineration in cement industries.

Pyrolysis

The plastic wastes are shredded and put into the pyrolysis unit. Plastics are catalytically converted into simpler organic compounds in gaseous, liquid and solid (char/carbon) forms. The gases produced are reused in the process for heating. The liquid hydrocarbon can be used as a substitute for furnace oil. The char has high calorific value and used in the briquetting plant.

Co-incineration

Plastic wastes are baled and sent for co-incineration cement manufacturing companies, with whom we have an agreement.